Working of Low-Pressure Compressed Air Dryer

A low-pressure compressed air dryer is specifically designed to remove moisture (water vapor) from compressed air operating at lower pressures. These dryers are essential in sectors like ash handling in power plants, cement plants, cleaning applications at pharmaceuticals, and general manufacturing, where moisture-free air is critical for:

- Protecting downstream equipment

- Ensuring reliable operation of pneumatic systems

- Maintaining product quality and hygiene standards

If moisture is not removed, it can lead to corrosion of pipelines, failure of pneumatic tools, and contamination of end products.

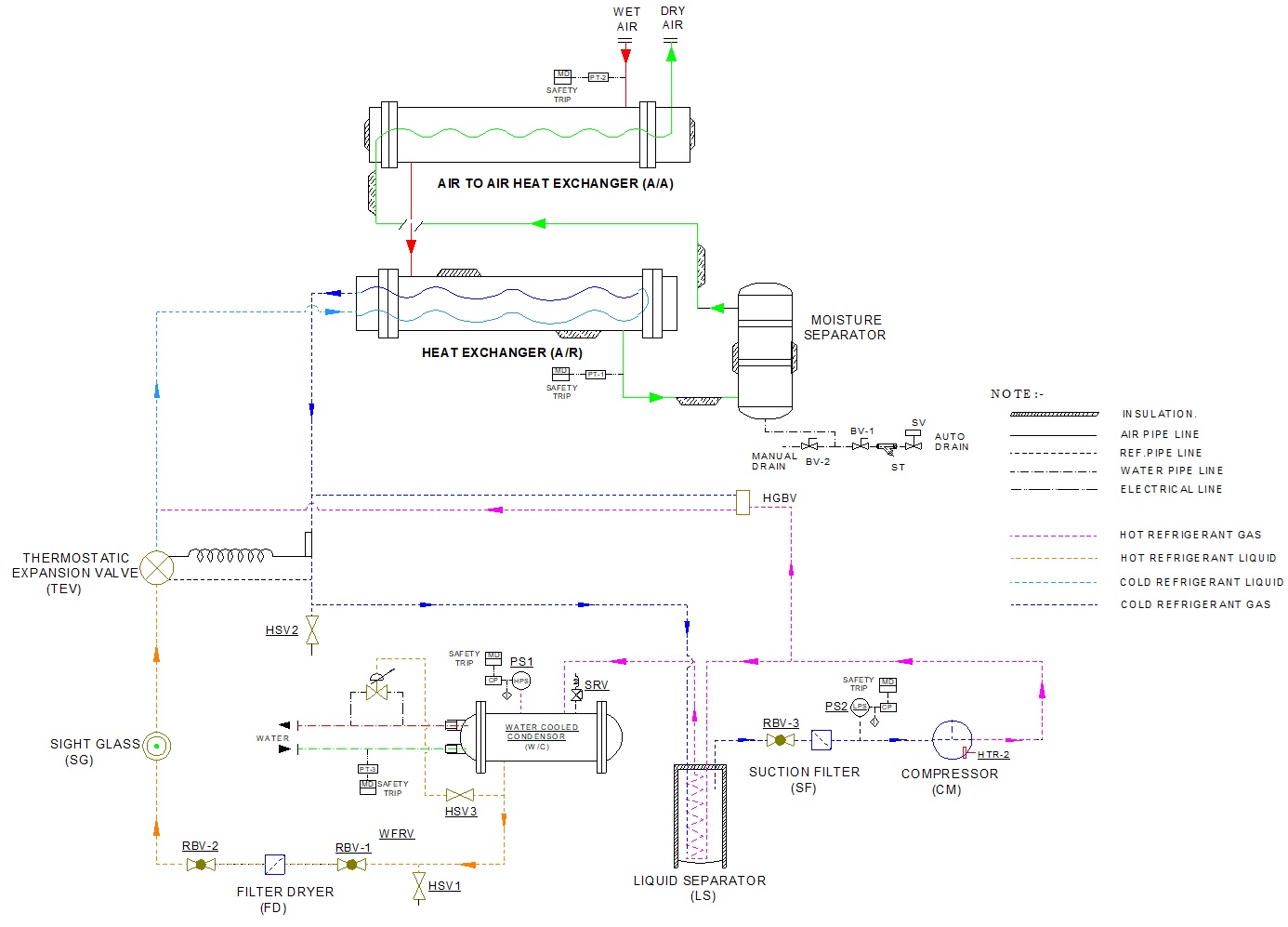

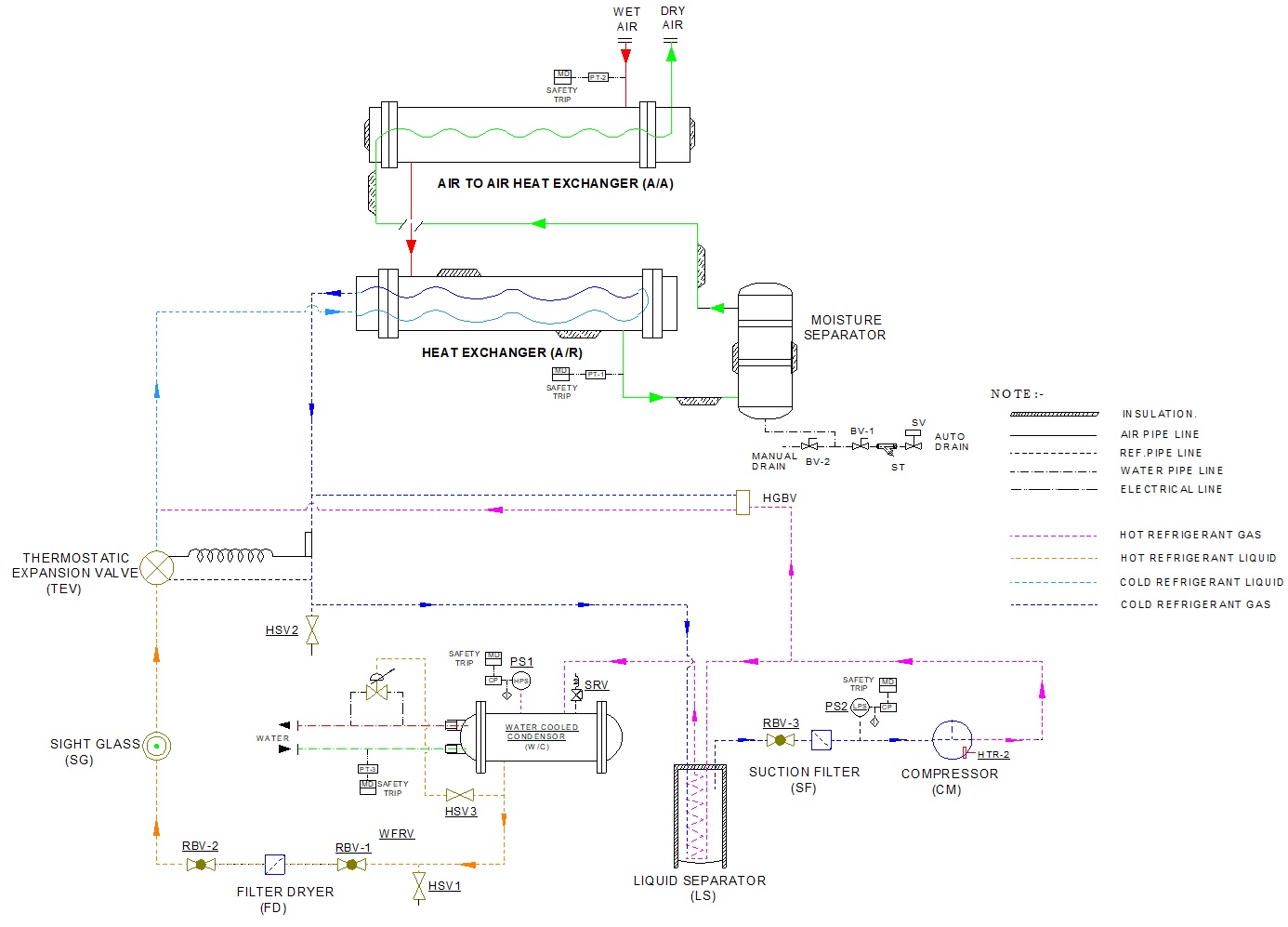

Working Principle – Refrigerated Type (Low Pressure)

The dryer operates on the principle of cooling the air to condense water vapor, which is then separated and drained. Here’s a step-by-step breakdown:

- Compressed Air Inlet

Low-pressure compressed air from the air compressor enters the dryer with high moisture content.

- Pre-Cooling – Air-to-Air Heat Exchanger (Pre-Cooler)

The incoming warm compressed air passes through a heat exchanger, where it is cooled by outgoing dry air. This pre-cooling step reduces the load on the refrigeration system and initiates partial moisture condensation.

- Deep Cooling – Air-to-Refrigerant Heat Exchanger (Evaporator)

– Air then enters the evaporator, where a refrigerant absorbs heat from the air.

– The temperature drops to around 3°C to 5°C, causing most water vapor to condense into liquid.

- Moisture Separation – Centrifugal + Demister Pad Separator

– The condensed water is removed using a centrifugal separator combined with a demister pad.

– Water is discharged via automatic or manual drain systems.

- Reheating (Optional) – Air-to-Air Heat Exchanger

The dry, cold air may be reheated slightly by exchanging heat with incoming air (via the air-to-air heat exchanger) to:

– Avoid condensation in downstream pipelines

– Improve energy efficiency

- Clean, Dry Air Outlet

The dry and slightly reheated air exits the dryer and is delivered to the system, now free from harmful moisture.

Process Flow Diagram

| MODEL |

Air flor

(in m3/hr.) |

Working Pressure

in.cm2(g) |

Dimensions

( L x W x H)

(in mm) |

Weight

(in Kg.) |

Water Qty.

(in m3/hr.) |

Power Consumption

(in KW) |

Air Connection

(in inch) |

Water Connection

(in inch) |

| FDI-1690W (LP) |

1450

|

4.0

|

2600 x 1000 x 1690

|

1500

|

5.00

|

5.00

|

4″

|

2″

|

| FDI-LP-1800W(SP) |

1803

|

1.7

|

2300 x 1100 x 1650

|

2800

|

9.00

|

9.00

|

6″

|

2″

|

| FDI-LP-2160W |

750

|

2.5

|

1800 x 950 x 1500

|

1050

|

4.00

|

4.00

|

4″

|

1.5″

|

| FDI-LP-2160W |

720

|

2.5

|

1800 x 950 x 1500

|

1050

|

4.10

|

4.10

|

4″

|

1″

|

| FDI-LP-2550W(S) |

1920

|

5.5

|

1800 x 850 x 1350

|

1200

|

25.00

|

25.00

|

4″

|

1.5″

|

| FDI-3000W(LP) |

2428

|

4.0

|

1800 x 850 x 1420

|

1200

|

6.00

|

6.00

|

4″

|

1.5″

|

| FDI-LP-4500W(S) |

4500

|

3.5

|

3200 x 1250 x 1925

|

2200

|

16.00

|

16.00

|

8″

|

2″

|

| FDI-LP-5400W(S) |

5400

|

1.5

|

3650 x 1250 x 2500

|

2500

|

13.00

|

13.00

|

10″

|

2″

|

| FDI-LP-5500W(SP) |

5100

|

2.2

|

3600 x 1500 x 2650

|

2300

|

15.00

|

15.00

|

10″

|

2″

|

| FDI-LP-5800W(SP) |

5800

|

1.7

|

4200 x 1600 x 2990

|

5000

|

29.00

|

29.00

|

12″

|

3″

|

| FDI-6000W (LP) |

6000

|

1.8

|

2400 x 1900 x 1835

|

5000

|

25.00

|

25.00

|

8″

|

3″

|

| FDI-LP-6000W (S) |

6000

|

2.3

|

2400 x 1900 x 1835

|

5000

|

25.00

|

25.00

|

8″

|

3″

|

| FDI-LP-6000W (SP) |

6000

|

1.5

|

4000 x 2000 x 2800

|

5400

|

18.00

|

18.00

|

12″

|

3″

|

| FDI-LP-6000W (SP) |

5800

|

3.3

|

3700 x 1250 x 2500

|

3000

|

15.00

|

15.00

|

10″

|

2″

|

| FDI-LP-6300W (SP) |

6300

|

2.0

|

3650 x 1250 x 2500

|

3000

|

15.00

|

15.00

|

10″

|

2″

|

| FDI-LP-6500W (SP) |

6200

|

2.8

|

3600 x 1500 x 2650

|

2500

|

16.00

|

16.00

|

10″

|

2″

|

| FDI-LP-6635W (SP) |

7000

|

2.0

|

2600 x 2000 x 2070

|

3000

|

25.00

|

25.00

|

8″

|

3″

|

| FDI-LP-6700W (SP) |

6306

|

2.7

|

3650 x 1250 x 2500

|

2500

|

15.00

|

15.00

|

10″

|

2″

|

| FDI-LP-6960W (SP) |

7000

|

1.5

|

2400 x 1900 x 1825

|

2500

|

25.00

|

25.00

|

8″

|

3″

|

| FDI-LP-6960W (SP) |

6600

|

2.8

|

2600 x 1900 x 1825

|

2500

|

25.00

|

25.00

|

8″

|

3″

|

| FDI-LP-7500W (SP) |

6710

|

2.5

|

4000 x 2000 x 2800

|

5400

|

34.50

|

34.50

|

12″

|

3″

|

| FDI-LP-7500W (SP) |

6100

|

1.6

|

4000 x 2000 x 2800

|

5400

|

24.00

|

24.00

|

12″

|

3″

|

| FDI-LP-7500W (SP) |

7200

|

1.3

|

4000 x 2300 x 2890

|

5400

|

19.00

|

19.00

|

14″

|

2.5″

|

| FDI-LP-9000W (SP) |

9000

|

4.3

|

4000 x 2000 x 2800

|

5400

|

21.00

|

21.00

|

12″

|

3″

|

|

Note: Higher capacities & Customised Requirements are available on request.

|