Login

Our Airgineers Can Help You Select The Right Product!

Contact Us

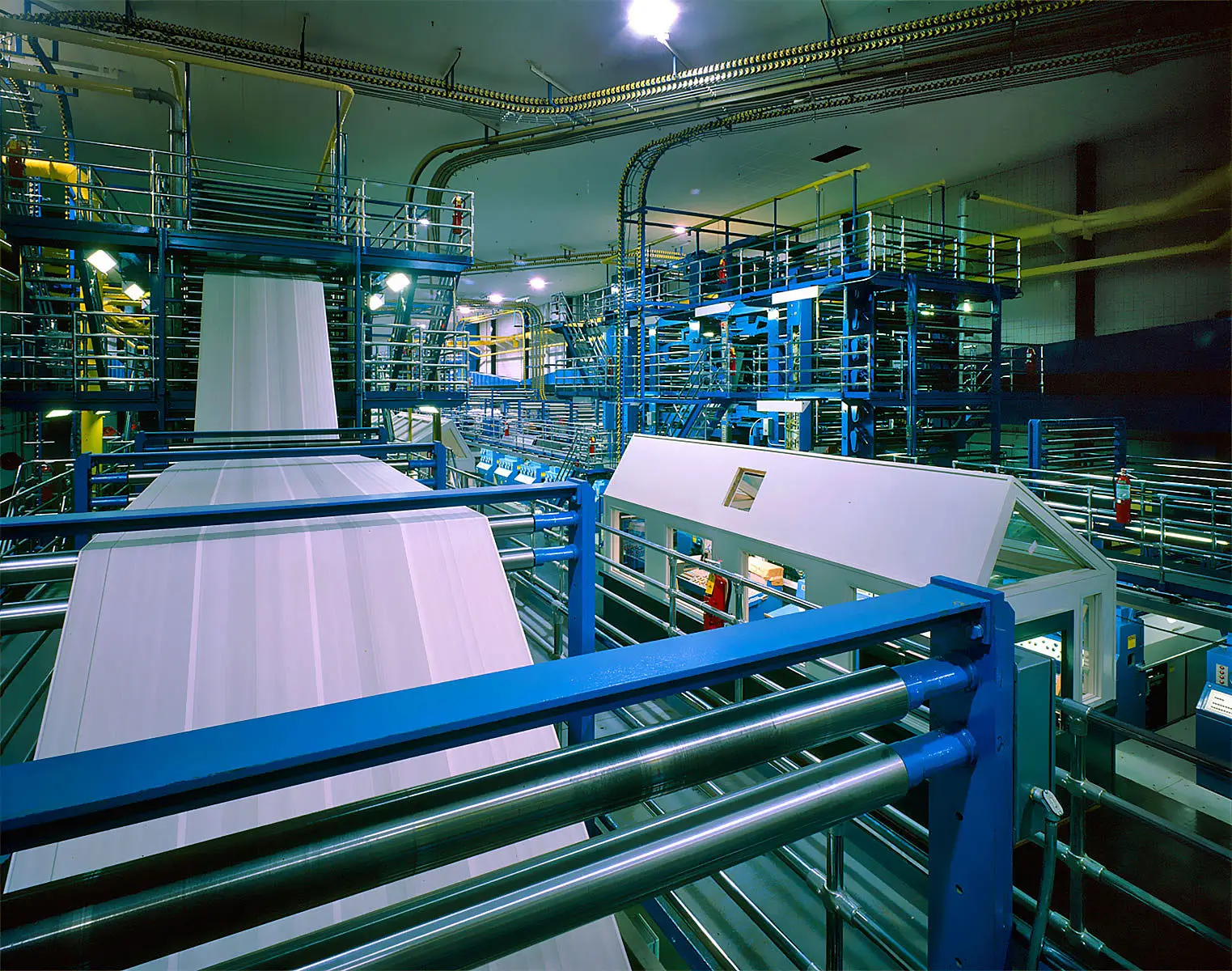

Printers and Publishers

Though you might not realize it, dry compressed air affects every unit in the Printing and Publishing industry.

Use of Compressed Air in the Printing And Publishers Industry

In Printing units, the following compressed air-powered pneumatic machines are used:

- Feeding Machine

- Pressing Machine

- Air Brush

- Press-fitting clap sleeves

Applications

- Roller adjustment

- Cutting paper

- Embossing

- Monitoring of paper reel

Problems

A major problem in compressed air systems is the presence of water, dust particles, oil (oil particles are introduced by lubricated air compressors), and solid contaminants, which can adversely affect air quality.

If the contaminated compressed air is used through pneumatic tools and machines, then there will be the following problems:

- Malfunctioning of pneumatic tools and machines

- Sluggish and inconsistent operation of valves and cylinder

- Corrosion in pipelines, cylinders and other components

- Increase in downtime

- Increase in maintenance cost of pneumatic machines/tools/controls

- Freezing in exposed lines during cold weather

Moisture in compressed air also leads to problems like :

- Loss of finish/gloss on the printing surface.

- Brittleness or unevenness of printed material.

- Poor print quality

- Increase in wastage due to dull and poor printing

- Sticking problems in automated material feeding and handling processes.

The Delair Solution

Remove water, dust particles, oil (lubricated air compressors introduce oil particles), and solid contaminants from compressed air.

Delair offers a wide range of refrigeration and adsorption dryers that remove water/moisture from compressed air.

Delair refrigeration dryers

This dryer operates on the method of cooling the air to near freezing point to remove the moisture and reheating it to approximately 10°C below the incoming compressed air temperature at nominal conditions.

Delair Adsorption dryer

The dryer is based on the principle of heatless regeneration and the physical properties of the desiccant to adsorb and desorb water vapour. It uses the pressure swing principle / purge air to regenerate the desiccant bed.

Filters

Delair also offers Pre Filters and Oil Filters, which remove dust particles, oil particles and other types of solid contaminants present in dry air.

Our Airgineers Can Help You Select The Right Product!

Contact Us